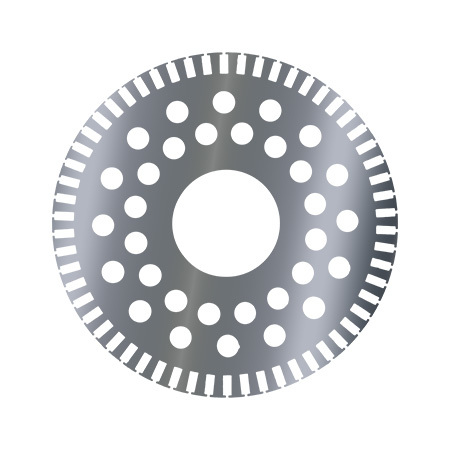

Aluminum centrifugal casting rotor

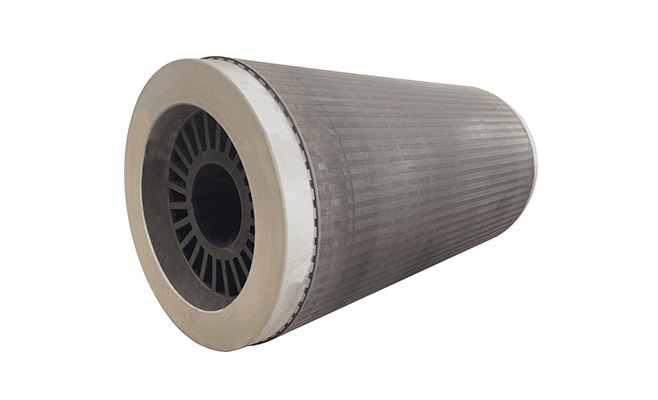

Rotor aluminum centrifugal casting is a method used to manufacture the rotor component of electric motors.

Aluminum centrifugal casting rotor 01

Aluminum centrifugal casting rotor

In this process, molten aluminum is poured into a spinning mold, which uses centrifugal force to evenly distribute the aluminum and fill the mold. This technique ensures a uniform, dense, and strong rotor with excellent mechanical properties. Centrifugal casting is particularly effective for creating rotors with a smooth finish and precise dimensions, enhancing the overall performance and durability of electric motors. The maximum centrigugal casting rotor size up to 1256mm diameter and 1400 height.

Related Ability